|

Thixotropic Systems |

DECAL DECORATION | ELECTROSTATIC COLOUR COATING SYSTEM | UV PRINTING SYSTEM THE KWIK CHANGE SCREEN SYSTEM | SCREEN MAKING EQUIPMENT | PRINTING ANCILLARIES DECORATING MATERIALS | QUALITY CONTROL | SPECIAL OFFERS

GLASS ENAMELS | INTRODUCTION TO GLASS ENAMELS | APPLICATIONS AND MEDIA

PHYSICAL PROPERTIES | FIRING PROCEDURES | THIXOTROPIC SYSTEMS

AMBER STAINING INKS | UV INKS | PRINTING FABRICS | STAINLESS STEEL PRINTING FABRICS

SYNTHETIC PRINTING FABRICS | SQUEEGEE BLADE | SCREEN MAKING MATERIALS

THIXOTROPIC ENAMEL SYSTEMS

The basic structure of the screening medium used for printing enamel inks assumes that requirements and conditions remain "standardised" throughout the printing process.

There are two situations in which 'ordinary' media are unsatisfactory.

Firstly, machine stoppages caused by breakdowns or broken glassware can subject the ink to higher than normal temperatures due to a longer dwell-time on the screen. When printing re-starts, the overheated ink floods the screen and can sometimes run through it, causing a series of misprints. This wastes ink, wastes production time and necessitates the need to clean-off many bottles so that they can be reprinted.

Secondly, where high definition is required, either because of fine lettering or logo detail, the natural 'flow' of an ordinary medium can obscure the finer detail. Even the use of fine screens cannot compensate for the natural movement of the enamel ink during printing.

These problems have been overcome by the use of a Thixotropic Medium.

By incorporating special additives, the natural flowing properties of the ink are minimised without affecting the inherent printing qualities. A printed line remains clean, precise and without the vague line work often associated with printed glass.

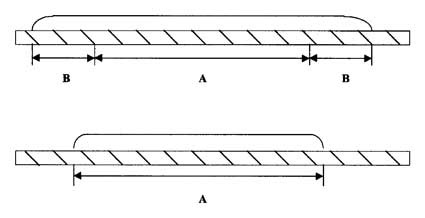

To illustrate the advantages more graphically, the following drawings show a magnified cross section of a line printed on a glass substrate with both conventional (1) and thixotropic ink (2).

The diagonally shaded area is the glass substrate. In the first drawing, the section 'A' shows the area of maximum colour strength whereas the area 'B' shows the reducing ink thickness caused by the natural flow of the ink.

This 'fall-off' area (B) on the conventional ink gives an imprecise line and, in the case of coloured inks, the colour will tend to appear weak at the edge of the print. The overall effect will be a logo which lacks impact and clarity.

Apart from the obvious advantages in print quality, thixotropic inks will not be liable to run through the screen during stoppages - irrespective of how hot the screen may become. This means that when printing is restarted, only the first one or two bottles may require cleaning and reprinting whereas with conventional inks, many bottles may become unacceptable until correct printing temperature and conditions are restored.

Inks should contain a thixotropic value designed as a compromise between high covering power, precise printing qualities and resistance to screen overheating. For special application, the thixotropic value can be adjusted to suit the exact conditions and requirements.